News

Dehumidifiers can be a very effective solution to the problem of steam removal and workshop humidity control in food factories. Especially in the production process of steamed buns, steamed buns, and steamed dumplings, a large amount of steam will be generated. These steam condenses into water mist in the air, resulting in excessive humidity in the workshop, which in turn affects production efficiency, equipment safety, and even food quality. Therefore, using dehumidifiers to control the humidity in the workshop is an important measure to improve the working environment.

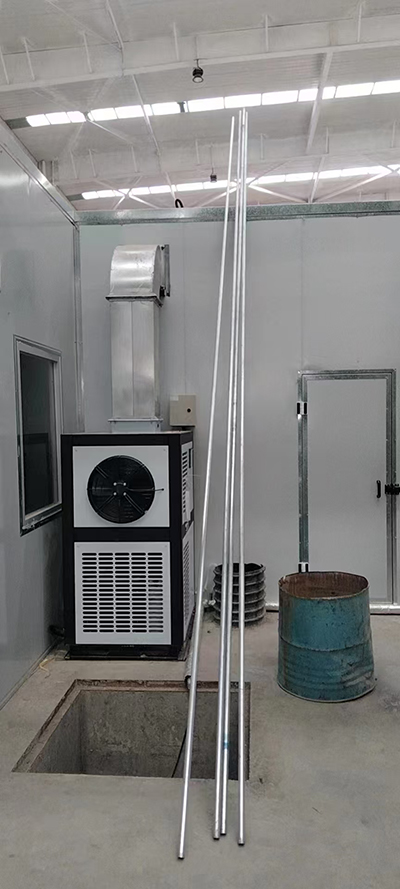

Food factory steam removal problem: application solution of dehumidifiers

- Reduce air humidity

- Improve air circulation and promote moisture discharge

- Choose the right dehumidifier model

- Installation location and distribution

- Maintenance and care of dehumidifiers

● The root cause of steam generation: Steam is water vapor generated by heating food or hot water, especially in the production process of steamed buns and steamed buns, a large amount of water vapor is released into the workshop air. The water vapor in the air condenses to form water droplets, called water mist, which causes the workshop to be humid.

● The role of dehumidifiers: Dehumidifiers reduce the humidity in the air by absorbing water vapor in the air, helping water vapor to no longer condense into water droplets in the air. In particular, industrial dehumidifiers can absorb moisture quickly and effectively to prevent excessive air humidity.

● Dehumidifiers are usually equipped with powerful fans and air circulation functions, which can accelerate the flow of air and help steam or moisture be sucked into the dehumidifier as soon as possible, thereby reducing the time that moisture stays in the air. By enhancing the air circulation inside the workshop, moisture can be quickly extracted, thereby reducing the formation of humidity and water mist.

● Large-capacity dehumidifier: Food factory workshops are usually large and humid, so it is necessary to choose a large-capacity dehumidifier suitable for industrial environments. According to the area of the workshop and the amount of moisture generated, choose a high-power device that can dehumidify efficiently.

● Humidity control and automatic adjustment function: Some advanced dehumidifiers are equipped with humidity sensors, which can automatically adjust the working mode according to the real-time humidity of the workshop to maintain a suitable humidity range. Generally speaking, the humidity control of food workshops should be between 50%–60%. Too high or too low will affect production.

● The installation location of the dehumidifier is very important. It should be as close to the moisture source as possible, such as the steam release port or near the heat source, so that it can absorb moisture more effectively.

● If the workshop is large, you can consider installing multiple dehumidifiers in different areas, so that the humidity can be reduced more evenly and moisture can be prevented from accumulating in a certain part.

● Dehumidifiers need to regularly clean filters, check water tanks, and remove accumulated water in time. After long-term use, the efficiency of the dehumidifier will be affected. Regular maintenance can ensure the long-term stable operation of the equipment.

● It is recommended to check the humidity control system regularly to ensure that the dehumidifier can automatically adjust according to the humidity of the workshop and will not cause problems with low or high humidity.

Advantages of dehumidifiers

● Stable control of humidity: Through continuous operation, the dehumidifier can maintain the humidity in the workshop within a stable range to avoid the impact of moisture on equipment and product quality.

● Environmental improvement: Dehumidifiers can not only reduce water mist and moisture, but also improve the working environment of employees and reduce the negative impact of moisture on employee health.

Specific application examples

1. Steamed bun workshop

● Problem: A large amount of steam is generated during the steaming of buns, resulting in excessive humidity in the workshop. After the steam condenses, water mist is formed, affecting the air quality.

● Solution: By installing multiple large-capacity industrial dehumidifiers, the workshop humidity is kept within a reasonable range (such as 50%-60%). The dehumidifier can continuously absorb moisture and prevent water vapor condensation.

2. Baking workshop

● Problem: High temperature and moisture are easily accumulated in the workshop during the baking process, affecting the baking effect and hygiene.

● Solution: By setting up a dehumidifier, the humidity in the workshop is reduced, making the air drier, which is conducive to product quality control, while keeping the workshop clean and reducing problems such as mold.

Sum Up

In the workshop of a food factory, especially in a production environment with more steam, a dehumidifier is an efficient and economical humidity control tool. It can reduce air humidity, reduce the condensation of water vapor into water mist, improve the workshop environment, and ensure product quality and production safety. Combined with appropriate air circulation and humidity control systems, it can greatly improve the work efficiency of the workshop and reduce equipment failures and maintenance costs.